INVESTMENT :

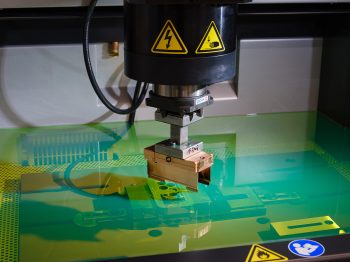

A new EDM machine has recently been installed in our factory.

At ASTIC, we constantly invest and modernise i.e. in March 2022 we installed a new EDM machine.

A REALLY IMPORTANT INVESTMENT

EDM is a process, where material is removed by means of electrical discharges.

There are many advantages in using this procedure.

This technology can be used on any conductive material regardless of its hardness.

For instance, treated steels, which can lead to breakages in traditional machinery, present no problem with this process.

EDM benefits from high precision, in the order of ± 5 μm and allows for the production of complex shapes that are nigh on impossible to produce through standard machining.

It also produces a completely uniform surface.

At ASTIC, EDM is employed, using copper electrodes, for certain elements of the plastic injection moulds we make. The arrival of the AG40L with its 12-station changer, the latest generation of machine, designed by SODICK – a Japanese company that is the leader in its field – ensures machining in almost half the time.

Performance, quality, reliability, comfort with easy tool handling, these machines include linear drive technology and simplified control mechanisms, which provide a direct link between drive and control.

Performance, quality, reliability, comfort with easy tool handling, these machines include linear drive technology and simplified control mechanisms, which provide a direct link between drive and control.

N.B: Respectful of the environment, SODICKs range of products, use energy-saving designs and technology. That reduce average energy consumption by up to 60%. This is one of the many reasons we adopted it.